Carbon dioxide (CO2) is a major respiratory metabolite, and continuous monitoring of CO2 concentration in exhaled breath is not only an important indicator for early detection and diagnosis of respiratory and circulatory system diseases, but can also be widely used for monitoring personal exercise status. KAIST researchers succeeded in accurately measuring CO2 concentration by attaching it to the inside of a mask.

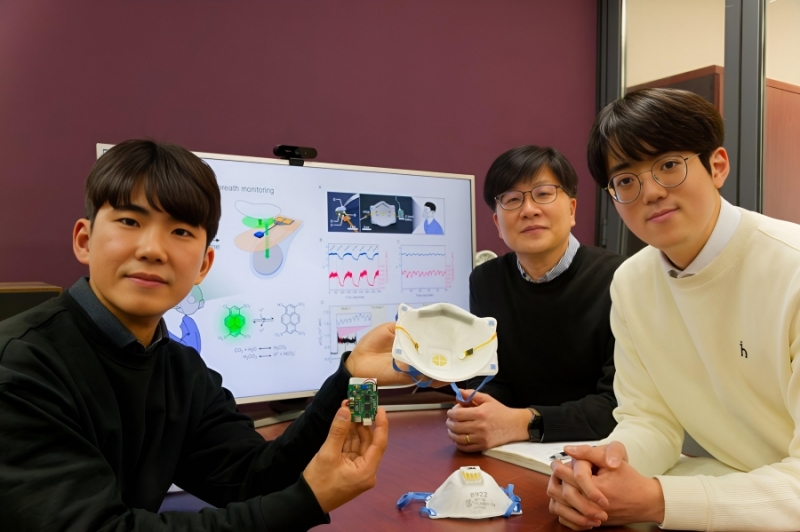

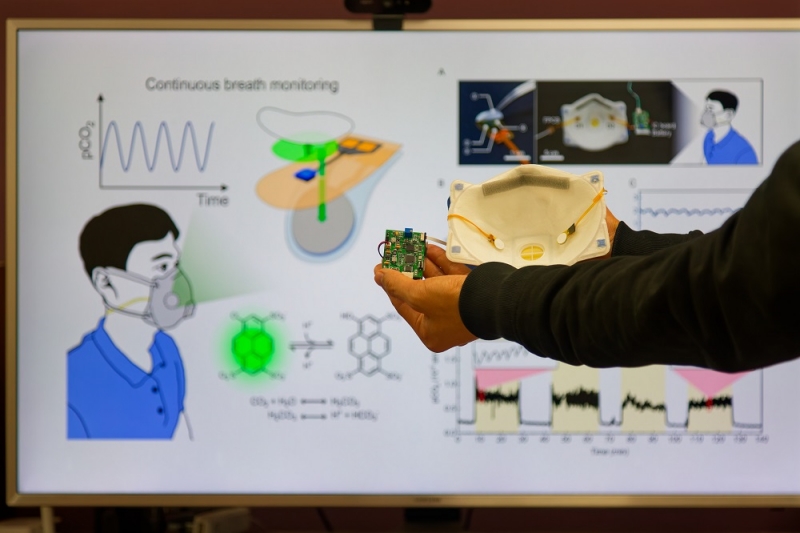

EE Professor Seunghyup Yoo’s research team in the School of Electrical Engineering have created a breakthrough wearable CO2 sensor. This new device enables real-time breath monitoring while maintaining low power consumption and high-speed performance.

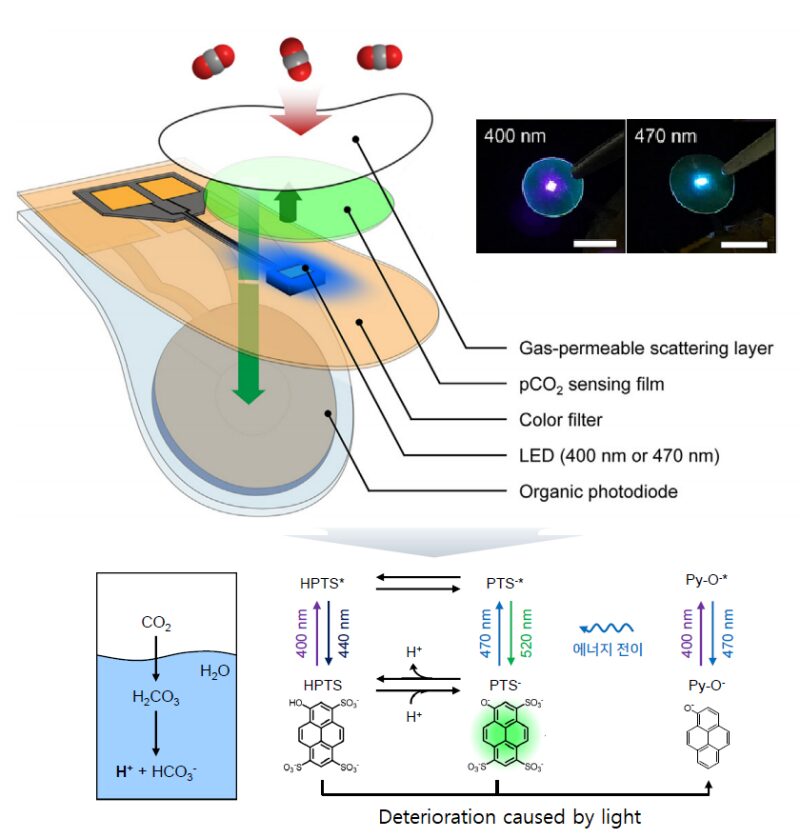

Traditional non-invasive CO2 sensors have been hampered by their bulky size and high power requirements. While optochemical sensors that use fluorescent molecules offer promising advantages in terms of size and weight, they also face a significant challenge: the fluorescent dyes tend to degrade over time when exposed to light. This instability has limited their practical use in wearable healthcare devices. As these optochemical sensors work by measuring changes in fluorescence intensity, which decreases with CO2 concentration, the key to their effectiveness lies in accurately detecting these fluorescence variations over a sufficiently long period of time.

To address these challenges, the research team engineered a low-power CO2 sensor that incorporates an organic photodiode that surrounds an LED. This design greatly enhances light collection efficiency and minimizes the exposure of fluorescent molecules to excitation light for a given level of signal. As a result, the device achieves power consumption of just 171 μW, which is substantially lower than the several milliwatts consumed by existing optochemical CO2 sensors.

The research team further elucidated the photodegradation path of fluorescent molecules used in CO2 sensors. They uncovered the cause of the increase in error rates over time in photochemical sensors, and proposed an optical design method to mitigate these errors.

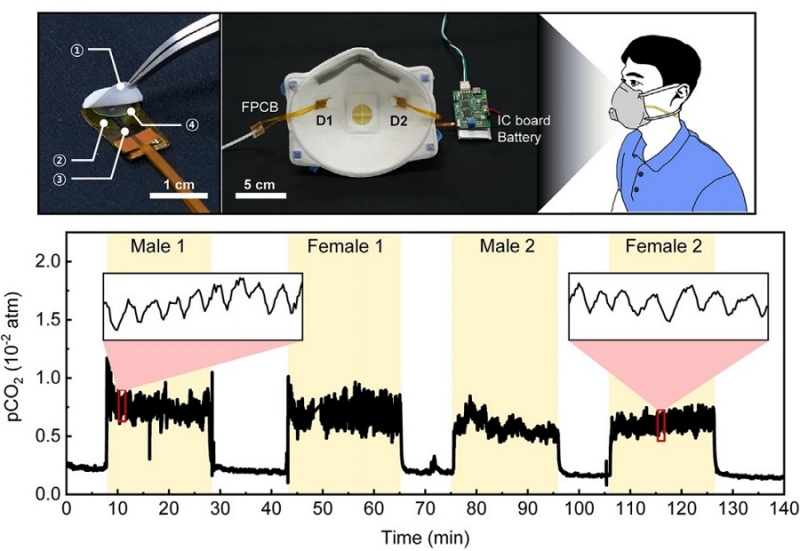

Building on these insights, the research team developed a sensor that significantly reduces errors caused by photodegradation, a persistent issue with previous photochemical sensors. Impressively, the new sensor maintains continuous functionality for up to nine hours—far surpassing the 20-minute lifespan of existing technologies—and can be reused multiple times simply by replacing the CO2-detecting fluorescent film.

The newly developed sensor, which is lightweight (0.12 g), thin (0.7 mm), and flexible, was effectively integrated inside a face mask. It boasts fast response times and high resolution, enabling it to monitor respiratory rates by distinguishing between inhalation and exhalation in real-time.

Professor Seunghyup Yoo commented, “The low power consumption, high stability, and flexibility of the developed sensor make it highly suitable for wearable devices. It holds great potential for the early diagnosis of various conditions, including hypercapnia, chronic obstructive pulmonary disease, and sleep apnea.” He also highlighted its utility in environments with high dust levels or where masks are worn for extended periods, such as during seasonal changes, noting its potential to alleviate the side effects caused by rebreathing.

This groundbreaking research was conducted with the involvement of Minjae Kim, an undergraduate student from Department of Materials Science and Engineering, and Dongho Choi, a doctoral student from the School of Electrical Engineering, as joint first authors, and published in the online version of Cell’s sister journal, Device, on the 22nd of last month. (Paper title: Ultralow-power carbon dioxide sensor for real-time breath monitoring) DOI: https://doi.org/10.1016/j.device.2024.100681

This study was supported by the Ministry of Trade, Industry and Energy’s Materials and Components Technology Development Project, the National Research Foundation of Korea’s Original Technology Development Project, and the KAIST Undergraduate Research Participation (URP) Project.