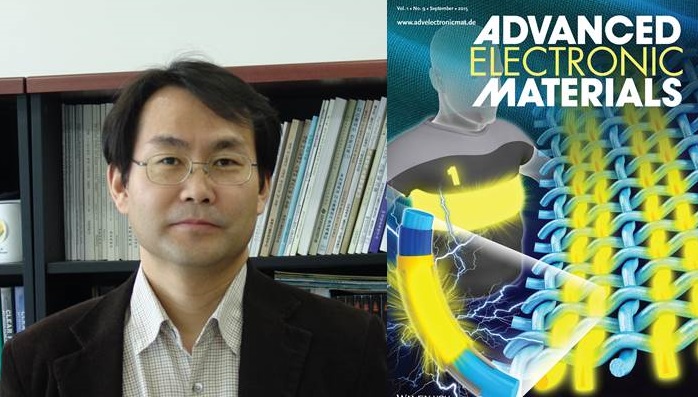

A polymer light-emitting display source technology was developed by the research team led by Prof. Kyung Cheol Choi and has been covered by numerous domestic and international news outlets.

The article in question, titled “High Luminance Fiber-Based Polymer Light-Emitting Devices by a Dip-Coating Method” by Ph.D. candidate Seonil Kwon from Prof. Choi’s lab and 6 other coauthors, was published in the September issue of the international journal, Advanced Electronic Materials, and was featured on its cover page.

<Main Press Releases>

[오늘의 과학자]옷처럼 편하게 입는 디스플레이가 나왔다 – Money Today page 19 column 2 2015.08.05.

‘섬유서 빛내는’ 유기발광 제작 기술 개발 – The Kyunghyang Shinmun Page A19 column 2

Arirang TV (15.09.11 방영): https://www.youtube.com/watch?v=J9keKez6ryY

<Published Article>

Link: http://onlinelibrary.wiley.com/doi/10.1002/aelm.201500103/epdf

Arirang TV “Bizline”(15.09.11 방영): https://www.youtube.com/watch?v=J9keKez6ryY

EE times Europe Aug. 19, 105

http://www.ledlighting-eetimes.com/en/fiber-like-leds-target-wearable-display-applications.html?cmp_id=7&news_id=222910070&page=0

Science Daily Aug. 11, 2015: http://www.sciencedaily.com/releases/2015/08/150811182913.htm

Innovation Toronto Aug12, 2015

http://www.innovationtoronto.com/2015/08/kaist-develops-fiber-like-light-emitting-diodes-for-wearable-displays/

Business Standard Aug. 17, 2015

http://www.business-standard.com/article/pti-stories/fibre-like-light-emitting-diodes-for-wearable-displays-115081700553_1.html

Asian Scientist Aug. 19, 2015: http://www.asianscientist.com/2015/08/in-the-lab/kaist-fiber-led-light/

Materials Gate Aug. 13, 2015

http://www.materialsgate.de/en/mnews/92842/KAIST+Develops+Fiber-Like+Light-Emitting+Diodes+for+Wearable+Displays.html

De Ingenieur, Aug. 28, 2015: https://www.deingenieur.nl/artikel/garen-geeft-licht

Yonhap News 2015.08.05. “옷감이 빛을 낸다”…유기발광 섬유 제작 기술 개발

Digital Times page 2 column 2 2015.08.05. `옷감이 스스로 빛을 낸다`

Money Today page 19 column 2 2015.08.05. [오늘의 과학자]옷처럼 편하게 입는 디스플레이가 나왔다

ETNews 2015.08.05. KAIST 연구진 섬유기반 유기발광 디스플레이 원천기술 개발

Asia Today 2015.08.05. KAIST, 섬유(실) 유기 발광 디스플레이 제작 원천기술 개발

University News Network 2015.08.05. KAIST, 섬유기반 유기 발광 디스플레이 원천기술 개발

Segye News page A25 column 2 2015.08.05. 옷처럼 입는 디스플레이 상용화 ‘눈앞’

Veritas-a 2015.08.05. KAIST 연구팀, 섬유 유기 발광 디스플레이 기술 개발

eDaily 2015.08.05. KAIST, 섬유 유기 발광 디스플레이 제작 기술 개발

The Kyunghyang Shinmun Page A19 column 2 2015.08.05. ‘섬유서 빛내는’ 유기발광 제작 기술 개발

EBN 2015.08.05. ‘옷처럼 입는 디스플레이 가능’…섬유 유기발광 제작 기술개발

중도일보 2015.08.05. [이코노미 줌in] 옷처럼 입을 수 있는 디스플레이 개발

아시아경제 2015.08.05. 유연성 뛰어난 섬유 자체에 발광 디스플레이 나왔다

뉴시스 2015.08.05. KAIST, 섬유 유기 발광 디스플레이 제작 기술 개발

뉴스1 2015.08.05. KAIST, 섬유 유기 발광 디스플레이 제작 기술 개발

충청투데이 2015.08.05. 섬유 기반 ‘유기 발광 디스플레이 원천 기술’ 국내 개발

충청일보 2015.08.05. 카이스트, 섬유(실) 유기 발광 디스플레이 제작 기술 개발

대전투데이 2015.08.05. KAIST, 섬유(실) 유기 발광 디스플레이 제작 기술 개발

뉴스타운 2015.08.05. KAIST, 섬유(실) 유기 발광 디스플레이 제작 기술 개발

금강일보 2015.08.05. [사이언스 ‘톡톡’] 옷처럼 편하게 입는 웨어러블 디스플레이 개발

YTN TV 2015.08.05. 빛내는 옷감으로 웨어러블 디스플레이 만든다

YTN사이언스 2015.08.05. 빛내는 옷감으로 웨어러블 디스플레이 만든다

YTN 2015.08.05. 빛내는 옷감으로 웨어러블 디스플레이 만든다

충청일보 2015.08.05. “옷감이 빛을 낸다”…유기발광 섬유 제작 기술 개발

YTN 2015.08.05. 빛내는 옷감으로 웨어러블 디스플레이 만든다